+86-18927501869

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

EnglishViews: 1101 Author: Allen Yi Publish Time: 2025-06-13 Origin: Site

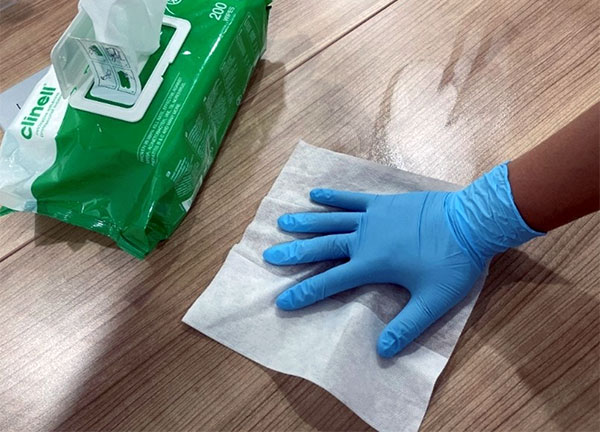

In today's hygiene-driven world, disinfectant wipes have become indispensable—from hospitals and hotels to schools and homes. Yet, behind every trusted wipe lies a crucial decision: which disinfectant wipes manufacturer you partner with.

Selecting the right manufacturing partner can determine your product's quality, safety, compliance, and market success. In this guide, we'll explain exactly what to look for in a reliable manufacturer, common pitfalls to avoid, and how brands like SYWIPE help global clients develop high-performing disinfectant wipes that meet international standards.

A disinfectant wipe is only as good as the factory that produces it.

Here’s why the manufacturer’s quality defines everything downstream.

A trusted disinfectant wipes manufacturer ensures every wipe:

• Contains the correct concentration of disinfectant actives.

• Delivers consistent performance across all batches.

• Maintains moisture and stability throughout its shelf life.

• Passes microbial and compatibility tests for both fabric and chemical.

Poor-quality production, on the other hand, leads to uneven wetness, contamination, or reduced disinfecting power, eroding customer trust.

Every market has its own hygiene standards—EPA in the U.S., CE/BPR in the EU, NMPA in China.

Non-compliant wipes risk recall, customs rejections, or fines.

A reliable manufacturer will guide you through certification, documentation, and label requirements—protecting both your product and reputation.

Choosing a manufacturer is not just about the lowest quote; it's about total reliability.

High-performing partners optimize:

• Raw material procurement

• Production scheduling

• Freight coordination

• Consistent quality control

• In short: lower defect rates, fewer delays, stronger profits.

The difference between an average supplier and a true long-term partner lies in technical depth and process control.

Use this checklist to evaluate any manufacturer.

Look for these must-have certifications:

• ISO 9001 / ISO 13485 (quality systems)

• GMP / ISO 22716 (cosmetics-grade manufacturing)

• EPA registration (for disinfecting claims)

• SGS or Intertek third-party reports

These credentials reflect real manufacturing capability—not just marketing promises.

A professional OEM disinfectant wipes supplier should have in-house chemists and laboratories to test:

• Kill rates and contact time

• Stability under different temperatures

• Fabric-chemical compatibility

• Shelf life and packaging integrity

SYWIPE's lab, for instance, supports custom formulations, accelerated aging tests, and complete documentation to meet client-specific regulations.

The wipe substrate defines your product's texture, absorption, and performance.

Common materials include:

• Spunlace nonwoven

• Airlaid or viscose blends

• Biodegradable fibers (bamboo, lyocell)

An expert manufacturer helps you match fabric with disinfectant chemistry—so your wipes don't dry out or react with actives.

Different markets require different chemistries:

• Alcohol-based (70% IPA/Ethanol) – fast-drying, hospital-grade

• Quat-based – non-alcohol, long-lasting surface protection

• Hydrogen peroxide – eco-friendly, broad-spectrum

• Natural botanical actives – for green product lines

An experienced custom disinfectant wipes OEM provides tailored solutions and documentation support for each market segment.

Ask your supplier:

• How many production lines do you have?

• What's your monthly output capacity?

• Do you have clean-room environments?

• Are lines automated with inline QC inspection?

SYWIPE operates multiple automated lines and ISO-class clean workshops, ensuring consistency across millions of wipes monthly.

Reliable manufacturers maintain:

• Stable raw material sourcing

• Global logistics partnerships

• Warehouse capacity for fast shipment

• Flexible MOQs for startups or scaling brands

That means smoother operations—even during global disruptions.

Eco-awareness is reshaping consumer demand.

A forward-thinking disinfectant wipes manufacturer should support:

• Biodegradable materials and eco-friendly packaging.

• Low-VOC and fragrance-free disinfectant options.

• Recyclable film and refill pouch systems.

• Carbon-reduction and wastewater treatment programs.

SYWIPE is actively developing plant-based wipes and biodegradable disinfectant formulations to help brands go greener without compromising effectiveness.

• Selecting purely by price leads to compromised quality or unstable formulas.

• Skipping documentation verification – results in legal or compliance risks.

• No pilot testing – you never know batch consistency.

• Ignoring contract clauses – lack of protection for defective batches or delays.

• Underestimating long-term collaboration – changing suppliers midstream is costly and risky.

• Remember: a low-cost deal today can cost you your brand tomorrow.

Clarify whether you need hospital-grade, household-grade, or eco-friendly disinfectant wipes.

Select manufacturers with proven expertise in regulatory markets like the U.S., EU, and Japan.

Ask for product data sheets, SDS, efficacy reports, and third-party lab validation.

Check cleanliness, production capacity, and quality control records.

(If you can't visit, SYWIPE provides virtual factory tours.)

Evaluate sample performance, stability, and customer feedback before scaling up.

With more than 15 years of OEM/ODM experience, SYWIPE has become a preferred partner for brands worldwide.

Here's why clients trust us:

• Advanced R&D with custom formula support

• EPA & CE-compliant production

• Multiple fully-automated nonwoven lines

• Private label & flexible packaging options

•100% quality inspection before shipment

• Global export expertise and fast delivery

From hospitals to retail, SYWIPE helps you develop safe, effective, and market-ready disinfectant wipes tailored to your audience.

Whether you're launching your first private label or upgrading an existing brand, the right manufacturing partner is the key to long-term success.

✅Contact SYWIPE today to discuss your product concept, formula options, or OEM partnership.

Let's create disinfectant wipes that protect people—and your brand reputation—worldwide.

A: Antibacterial wipes kill bacteria; disinfectant wipes kill viruses & bacteria.

A: Yes, OEM manufacturers can adjust formulas for your needs.

A: Typically 2+ years if stored properly (check expiration dates).

A: Only if alcohol-free & non-toxic—always check labels.

Top 8 Global Wet Wipes OEM Manufacturers: 8 Best Wet Wipes OEM

Global Wet Wipes Market Report: Global Wipes Market - Industry Trends and Forecast to 2030

Sustainability in Wet Wipes Production: Biodegradable Wet Wipes: Eco-Friendly Solutions for Sustainable Hygiene

Our Customers Always Come First

Trust is the Foundation of Our Service

sales@clean-wipe.com

sywipe@clean-wipe.com

Room 4611, No. 372 Huanshi East Road, Yuexiu District, Guangzhou,China.

+86-18927501869 / +86-20-81608597

/ +86-18927501869