+86-18927501869

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

EnglishViews: 119 Author: Allen Yi Publish Time: 2023-09-30 Origin: Site

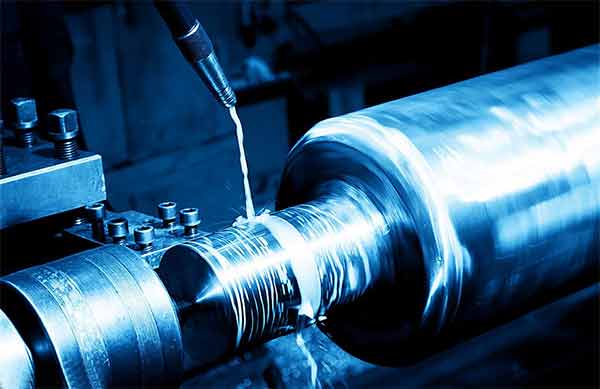

In the realm of industrial machinery, maintaining and ensuring the pristine condition of machine parts is paramount. Over time, machinery parts often accumulate stubborn contaminants like unsaponifiable oil, dust, and other impurities which, if not tackled timely, can hinder the machine's efficiency.

So, our elaborates on various cleaning methods, whether you're looking for manual removal techniques or aiming to use high-tech mechanical tools. Enter SYWIPE – a leading factory from China in the world of industrial wipes, specially designed for grease removal.

When dealing with the intricacies of industrial machinery maintenance, one of the frequent challenges is the removal of persistent contaminants. Especially when it comes to oil-based stains, the residue formed from unsaponifiable oil, dust, and impurities can compromise machine efficiency. Industrial wipes for grease have been specially developed by SYWIPE leading China manufacturers to address these nuances.

1. Hierarchy of Cleaning: Address the external contaminants before moving inwards; tackle light residues before addressing the heavier, more embedded grime.

2. Material-Specific Approach: Different materials, including rubber, asbestos, and resin, demand specialized cleaning solutions. Always refer to guidelines provided by industrial wipes for grease manufacturers for best results.

3. Dirt-Specific Strategy: Adjust the cleaning technique based on the nature of the dirt. For instance, industrial wipes for grease would be optimal for oil residues, while other methods might be better suited for scale or rust.

1. Precision Cleaning: While ensuring thorough cleanliness, it's imperative to keep the machine parts, especially precision-machined surfaces, damage-free.

2. Processed Surface Care: For such surfaces, turn to lint-free industrial wet wipes. Avoid abrasive tools that can jeopardize the surface quality.

3. Protection of Moving Parts: If a moving part has an anti-rust layer, immobilize it during the cleaning process to maintain its integrity.

4. Post-Cleaning Protocol: Post-cleaning, parts should be lubricated before being covered with moisture-proof paper, safeguarding them from dust and contaminants.

5. Floor Safety: Prevent any oil or solvent spillage on concrete floors. This is crucial both for safety and equipment longevity.

6. Flammable Solvents: If your cleaning involves such solvents, prioritize fire prevention and ensure optimal ventilation.

1. Manual Removal: This includes the use of industrial wipes for grease, coupled with manual tools, to eradicate surface contaminants.

2. Mechanical Tool Cleaning: This method capitalizes on electric or pneumatic tools. Paired with industrial wipes for grease, this method ensures a deeper cleaning of carbon deposits and rust.

3. Compressed Air Cleaning: A method to displace dry contaminants like dust and sludge.

4. High-pressure Water Cleaning: Especially effective for certain stubborn residues.

5. Abrasive Cleaning: Utilizing abrasives, this method breaks down and removes the most stubborn of contaminants.

With a strategic integration of expert-recommended practices and the specialized efficiency of industrial wipes for grease, machinery maintenance transcends to a new level of excellence.

In the evolving landscape of machinery maintenance, the importance of specialized cleaning products cannot be overstated. As highlighted, using industrial wipes for grease offers a solution tailored to address specific challenges faced in workshops. As industries continue to demand precision and efficiency, turning to trusted industrial wipes from China suppliers ensures not just quality but also an assurance that your machinery will function at its optimal capacity. With the right tools and products, provided by leading industrial wipes China suppliers, we can elevate the standards of machine maintenance and prolong the life of our invaluable equipment.

Sywipe seizes every opportunity to use high-quality resources, including peer-reviewed research, to support the facts in our article.

Learn more about our factory and how to keep the content accurate, reliable, and trustworthy.

1.《Why Industrial Wipes are Crucial for Cleaning Dirty Hands in Industrial Settings?》

2. 《How to Cleaner Dirty Hands With Heavy-Duty Industrial Hand Cleaning Wipes?》

3. 《How to Easily Remove Acrylic Paint with Industrial Cleaning Wipes?》

Our Customers Always Come First

Trust is the Foundation of Our Service

sales@clean-wipe.com

sywipe@clean-wipe.com

Room 4611, No. 372 Huanshi East Road, Yuexiu District, Guangzhou,China.

+86-18927501869 / +86-20-81608597

/ +86-18927501869